As shown inside the desk earlier mentioned, the more situations the sheet metal is bent, the bigger the bending tolerance turns into. This makes it tricky to maintain the accuracy of the scale of the several bends within the sheet metal.

The fabric is then immersed in a very molten zinc bathtub at a temperature of around 460°C to provide a zinc-coated substance. SGCC is more challenging than SECC but has lousy ductility, a thicker zinc layer, and weak weldability.

To prevent this, it’s crucial that you be certain that there are no other characteristics blocking the urgent by trying to keep a minimum of two times the thickness of the sheet metal as well as the bending radius clear at the base from the sheet metal, as demonstrated within the accompanying figure.

Inspite of its positive aspects, There are many downsides to utilizing sheet metal. Just one main problem I’ve encountered is its susceptibility to warping and distortion through the fabrication system.

To easily transform gauges into inches or millimeters, take a look at our sheet metal gauge chart. Find out more concerning the distinctions concerning metal sheet and plate.

Shearing is a simple mechanical process that utilizes a blade to trim the edges or make straight cuts. In contrast, laser reducing employs a centered laser beam that easily melts with the metal, leading to specific cuts and minimal product waste.

The website L.L.Bean sheets wrinkle somewhat more than our sateen picks but not more than any of the opposite major-position percale sets that we tried out. Picture: Michael Hession

We don’t recommend shelling out quite a bit on dorm sheets since you’ll utilize them For less than a 12 months or two. But we do propose finding one hundred% cotton sheets around jersey knit or microfiber, which can be incredibly hot to snooze on. And these are typically the ideal economical, all-cotton sheets we’ve ever tried out. Focus on also offers a just one-calendar year return coverage for these sheets when they don’t work out.

The minimum sheet metal bending height needs to be calculated as two situations the thickness of the sheet metal furthermore the bending radius, i.e., H ≥ 2t + R.

Deep drawing Deep drawing equipment is comparable to that on the shear punch but this time There exists far more clearance amongst punch and die which generates the final wall thickness of the drawn section.

But what precisely is sheet metal? And What exactly are the different sorts of sheet metal readily available? This complete manual from MachineMfg offers each of the answers.

The terminology employed when speaking using a metal roofing contractor might be baffling. Our Metal Roof Glossary will let you have an understanding of the conditions, and assist you make clever conclusions. Master metal roofing terminology.

All holes and cutouts are at the least fifty% substance thickness and sufficiently spaced away from the die line

The answer with the holes on The 2 bends of your sheet metal is difficult to align because of the huge bending tolerance:

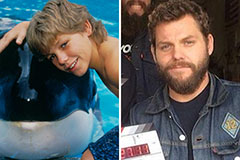

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!